Making CAD education accessible to anyone, anywhere.

We hope you’ve been enjoying the wealth of free Fusion training provided by Product Design Online. Our commitment to empowering individuals like you with valuable skills is at the core of what we do.

If you’ve found our free content beneficial in your learning journey, we kindly ask for your support through a donation. Your contribution will not only help sustain the availability of free materials but also enable us to expand our offerings and reach even more learners globally.

Please select a donation method

Pixel 3 Demo File

Autodesk Fusion phone file: https://a360.co/3TCk4dm (original phone file is from GrabCad.com)

Use this file if you’d like to follow along with the same file in the tutorial. If you’d like to follow the process for your phone, then follow the recommendations below.

Phone 3D Models

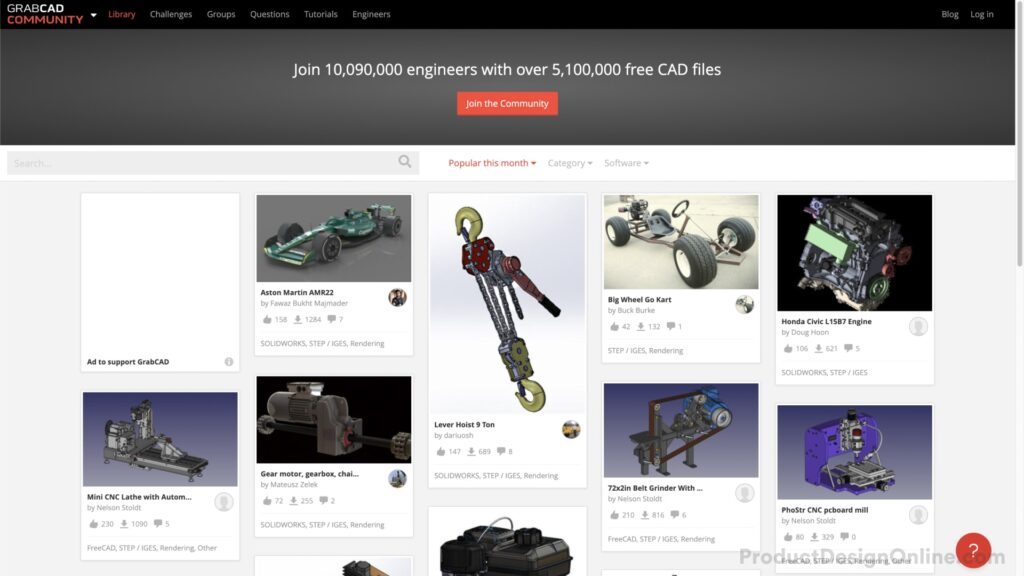

Websites with CAD data can vary greatly. The following three sites are what I often search for first when looking for existing CAD data to build from or reverse engineer.

- Grabcad.com (best for finding STEP files or other native formats).

- Thangs.com (best for general models, and creativity, including many for 3D printing)

- Thomasnet (best for gears, mechanisms, and more)

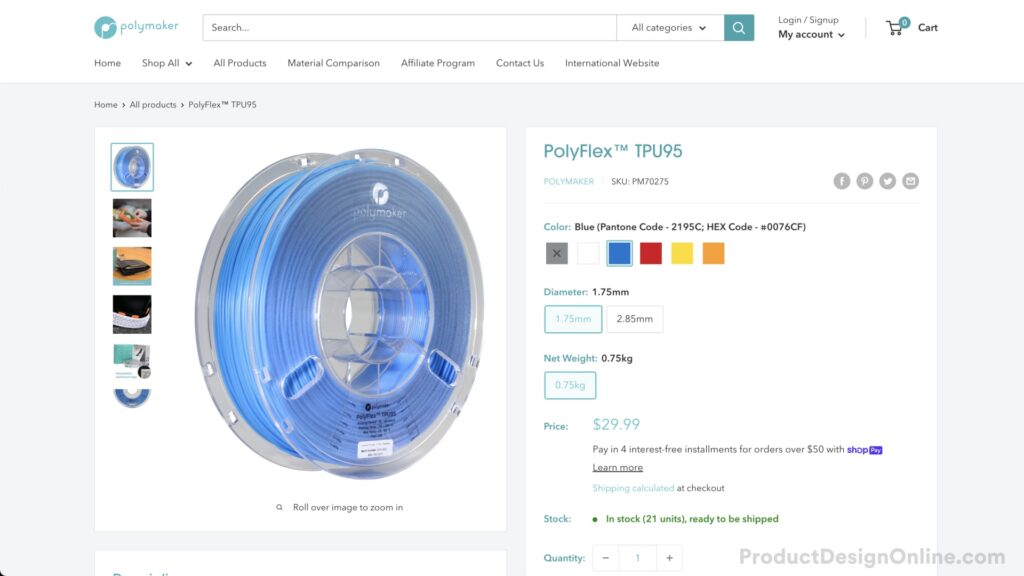

Recommended Flexible Filament (TPU)

PLA and ABS will not work well for 3D printing a phone case, unless your simply printing it for fun. If you’d like a functional phone case, you’ll want to purchase a flexible TPU filament. I recommend Polymaker TPU-95A. Out of all the flexible filaments I’ve used over the years, Polymaker has proven to print with the best results and the least amount of fuss.

That said, printing TPU is typically more challenging than PLA. You’ll want to lower your cooling fan speed to ~20%, and up your printing temperature to 230 degrees Celsius. The first few layers are very critical as TPU does not always stick well to all build platforms. Consider using blue painter’s tape or a glue stick on a glass build plate if you have issues with the filament sticking.

For any other troubleshooting – please ask in the PDO Community.

Transcript

Welcome to Day #10 of Learn Fusion 360 in 30 Days. I’m Kevin Kennedy,

and today we’ll create a custom phone case while Sweeping sketch profiles around existing 3D models.

To get started, you can almost always find a free 3D model of popular smartphones online, which will help us quickly build the phone case.

I recommend starting with GrabCAD.com, and I’ve placed more recommendations in the video description.

You’ll want to find a STEP file when a native Fusion 360 file isn’t available. The STEP format is a widely used data exchange format accepted by many CAD programs. Most importantly, it’s a solid BREP body that we can leverage in Fusion 360.

In Fusion 360, we’ll use File > Open to import the design from our local computer. Select the file and “Open” it.

Any imported STEP files will place you in Direct modeling mode, which means the parametric timeline is turned off.

Right-click on the “Root” or “Top-level” component and select “Capture Design History.”

The parametric timeline is now turned on and will record each feature.

You’ll also want to right-click on the body and “Create Components from Bodies,” as this will let us use Joints and additional workflows.

The orientation is a common problem with imported geometry. We can quickly fix this by applying a Joint to the back of the phone and our Center Origin. Now the phone is lying flat on the table.

Every phone will have some differences, but we’ll look at the core workflow to quickly create a 3D Printable phone case.

We’ll start by Sweeping a shape around the edge of the phone.

Let’s first create a New Component for the Phone Case. We can rename the components. Make sure the Phone Case component is active.

We’ll activate “Create Sketch” and select our origin plane.

Instead of manually tracing the edge of the phone, we can use the Project command to project existing edges into our sketch. Activate “Project” with the shortcut letter P.

We can then select the edges of the phone, being careful not to select the faces of 3D bodies. There appear to be four edges with this file as they’re divided by these cutouts in the phone model.

Click OK once complete.

Hiding the Phone component will help us see this. Remember, Projected geometry is Purple, which reminds us it’s referencing existing 3D bodies.

We’ll want to factor in a small clearance for the phone case. However, let’s first use the 3-point arc command to close the gaps.

I’ll intentionally make this arc’s center point away from the other, allowing us to shift-click the projected center point and the arc’s center point. We can then use the Coincident constraint to force these to remain the same. Repeat for any remaining gaps.

The Offset sketch tool will let us factor in our clearance. After selecting each sketch segment, I’ll define a .25mm offset. This will create a total clearance of 0.5mm since we’re sweeping this around all four sides.

With the Line tool, I’ll create a rough shape that we’ll sweep. Fusion 360 will attempt to place automatic constraints, so try to place the lines where it’s perpendicular to the previous line.

Add a sketch dimension of 1.25mm to the top.

I’ll make the bottom 2mm.

To fully define the sketch, we’ll add a dimension for the thickness between the arc and vertical line. This will be 2mm as well.

Now that we have our fully closed profile, activate the Sweep command and select the profile.

With the path selector, we’ll reference the edge of the phone. Just like that, we have a basic bumper around the phone.

I like to add a quick visual appearance when designing to help distinguish the parts.

Let’s add Fillets to soften the sharp edges. I’ll do 2mm for the top edge, and with a new selection set, we can define a different size on the bottom, such as 3mm.

Currently, the top inner edge is too close to the phone screen. We can select the four inner planer faces. Selecting faces on each side will allow us to use the shortcut letter “Q,” as in Quebec, to access the Offset faces feature. I’ll set this back -1mm.

I’ll also add a 1.25mm Chamfer to the inside edge. The Chamfer will reinforce the overhang and will 3D print better than a small Fillet.

Create a Sketch on the back planar face. You’ll want to use Project again, this time referencing the existing edges of our phone case. Be sure to include any cameras or fingerprint sensors as well.

After projecting the geometry, turn off the Phone component, which will allow us to Offset the camera and sensor openings. I recommend a minimum offset of 1mm.

Most phones also have sensors and flash next to the camera. Take a minute or two to sketch out some additional geometry next to the camera hole.

Once complete, Extrude this at the same distance as the bottom of the sketch profile. I used 2mm.

I also recommend adding a Chamfer to these edges, set to the same thickness.

Don’t forget to create openings for any charging ports and buttons to finalize the phone case.

Start with a sketch of where the charging port will go.

Hide the phone case and turn the phone back on.

We can then Project the edges of the charging port. In this scenario, we can choose to offset these sketches, or we can offset the 3D body.

I’ll turn the phone case back on and use Extrude to cut this out, cutting this up to the inside wall.

Select the inner faces, and use the shortcut letter “Q” to Offset this at least 2mm to allow room for the charging cable.

In preparation for printing with TPU, I recommend applying a 1 to 2mm Chamfer on any side openings. Small Chamfers will print much better than Small Fillets due to the layer lines.

Simply repeat this process for any remaining buttons.

Now that the overall phone case is complete, I encourage you to have fun by creating your own custom design on the back panel. This can be done by simply sketching out the desired text, logo, or design. Then, Extrude cut the shape from the 3D body.

[Upbeat Music]

You’ve successfully completed the phone case! I’ll see you on Day 11 where we’ll 3D model a dog bowl.

[End Upbeat Music]

Leave a Reply