3D printers are increasingly popular among hobbyists and consumers. You’ve likely seen one in a YouTube video or may have a friend that owns one. In 2022, do you truly need one for your home?

To better understand if a 3D printer is right for you, you’ll need to understand the fundamentals of how they work. Apprehending their methods will help you better understand what they’re capable of making.

Table of Contents

- Four Types of 3D Printers

- Materials for FDM (FFF) Printers

- How FDM 3D Printers Work

- Design of a 3D Printer Machine

- How 3D Printers Create Your Design

- Cost of Hobbyist 3D Printers

- Drawbacks of Consumer 3D Printers

- Summary of How 3D Printers Work

Four Types of 3D Printers

3D printers use many different technologies and processes referred to as “Additive Manufacturing.” In short, all 3D printers start with nothing and continue to add material until your part is complete.

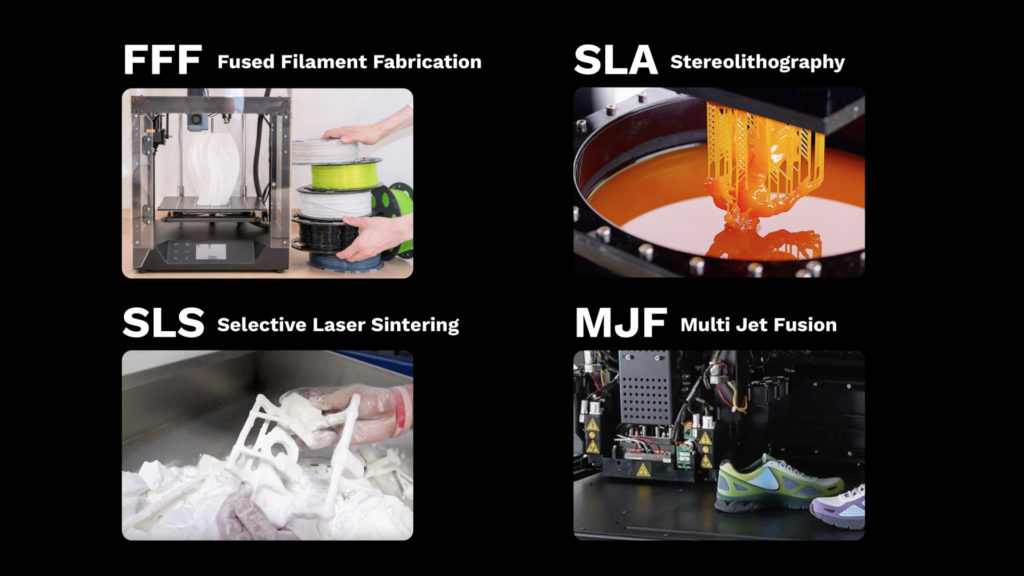

The following four 3D printing processes represent the most common.

- Fused Filament Fabrication – Also known as FFF or FDM, is the process of taking a thermoplastic material pushed through a heated nozzle. FDM 3D Printers are the most common (with consumers) and affordable method.

- Stereolithography – Also known as SLA, or a “resin printer,” uses a light source (laser or projector) to cure liquid resin into hardened plastic. Fun fact – SLA was the first type of 3D printer invented.

- Selective Laser Sintering – Also known as SLS, is a 3D printing method that uses a laser to sinter (compact) nylon or polyamide into the desired 3D print.

- Multi Jet Fusion – Also known as MJF, uses an inkjet array to apply fusing agents to the bed of nylon powder. MJF is one of the most popular methods for full-color 3D prints.

Some remaining types include Selective laser melting (SLM), Laminated object manufacturing (LOM), Polyjet, and Digital Beam Melting (EBM). Many of these are variations of the 3D printer types above.

Because FDM (or FFF) machines are most popular among home-use 3D printers, we’ll focus on them for the rest of this article!

Materials for FDM (FFF) Printers

Let’s look at the available materials before we take a closer look at FDM machines. Looking at the materials will help you understand how the machines work.

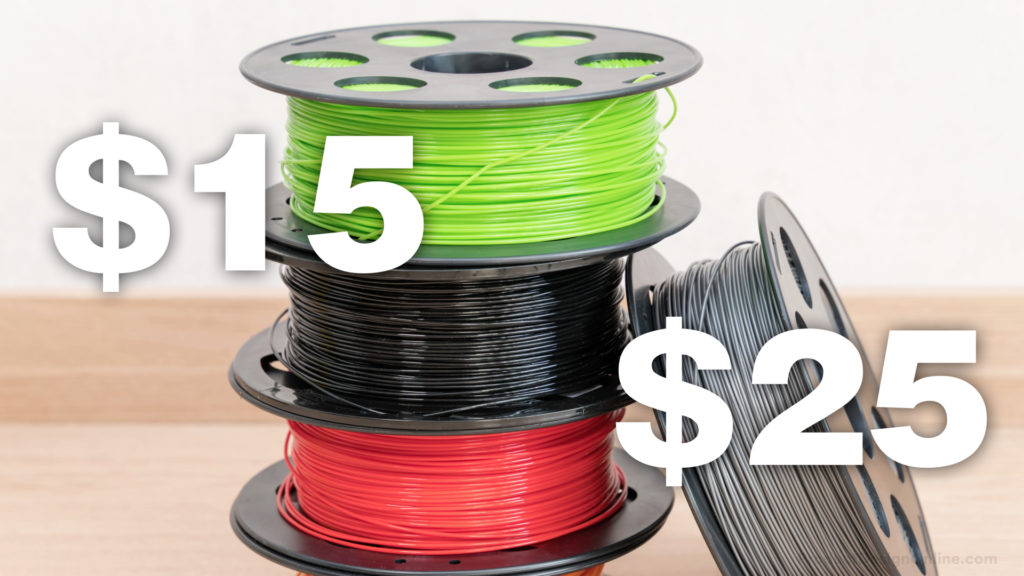

FDM 3D Printer materials come in spools that are called filament. Spools of filament typically cost $15-25 (US dollars). The price range of filament will depend on the brand, type of material, size, and quality.

3D printer filament comes in PLA, ABS, Nylon, TPU, PETG (PETT), and less common materials such as wood-filled, and more. Most 3D printing hobbyists use PLA (most common) or ABS as they’re affordable and easy to use.

How FDM 3D Printers Work

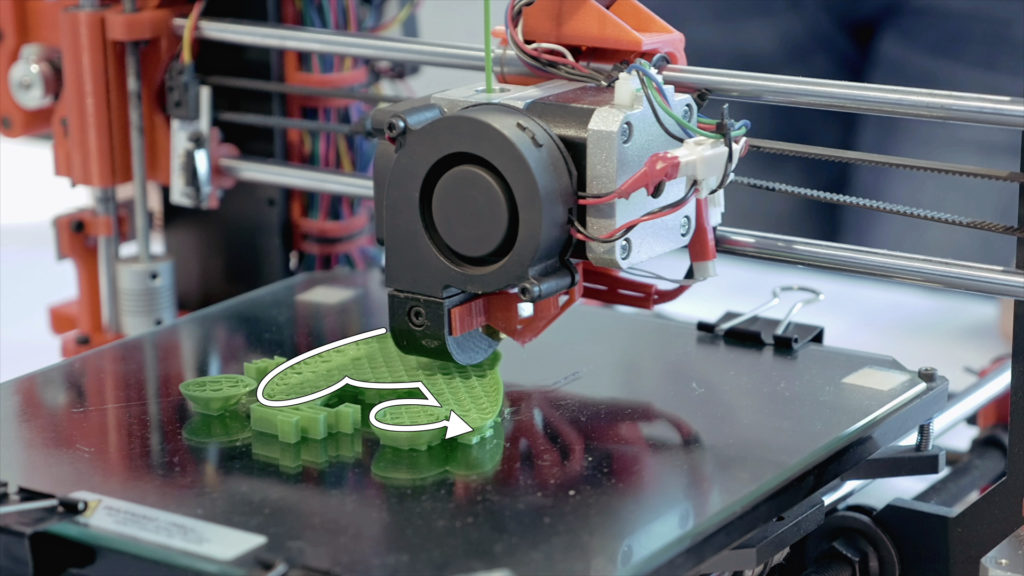

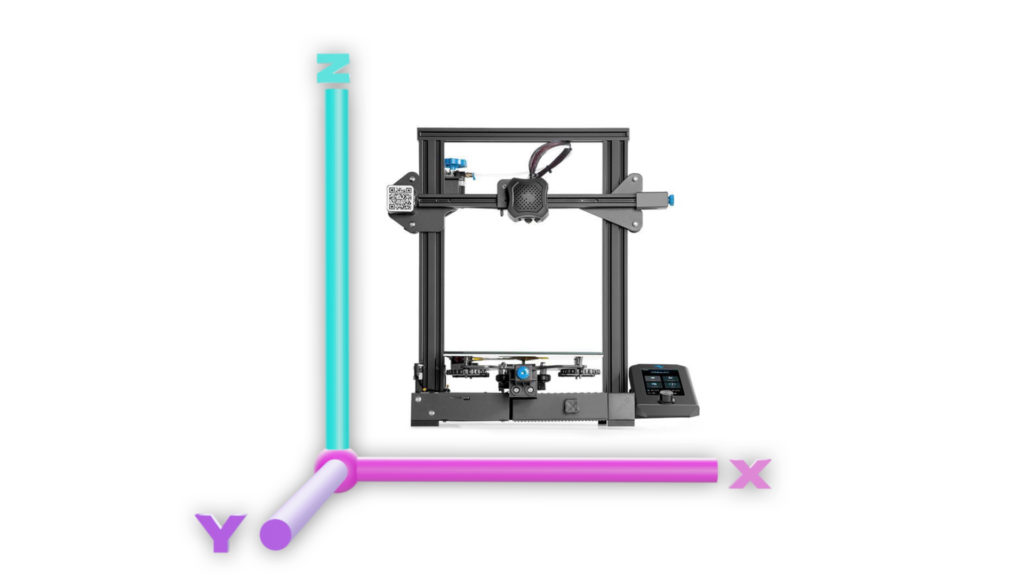

In simplest terms, the filament (material) is pushed through a heated Extruder at a continuous rate, while the Extruder moves around the X and Y-axis. This movement allows a 3D Printer to trace your chosen design, layer by layer.

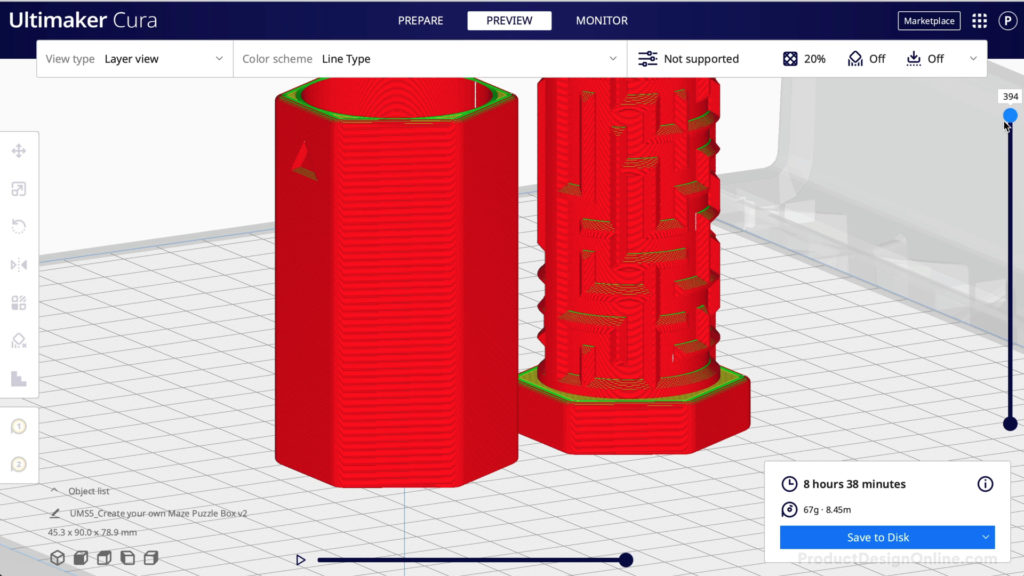

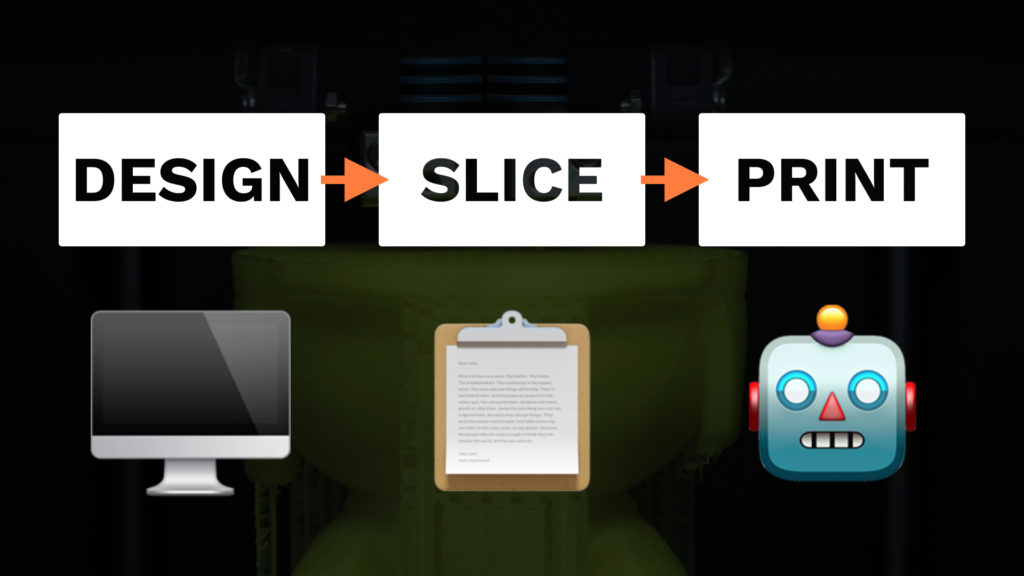

Once you select or create your design, open it in one of many software programs called a slicer. Most slicing software accepts 3MF, STL, and OBJ mesh files.

Slicing software will then translate your 3D model into lines of code that represent very-thin layers. On average, these layers are typically only 0.1 or 0.2mm thick. You can think of this as cutting a vegetable into paper-thin slices.

The simplicity of this process may surprise you. Behind the scenes, the software will write the machine instructions as lines of G-code.

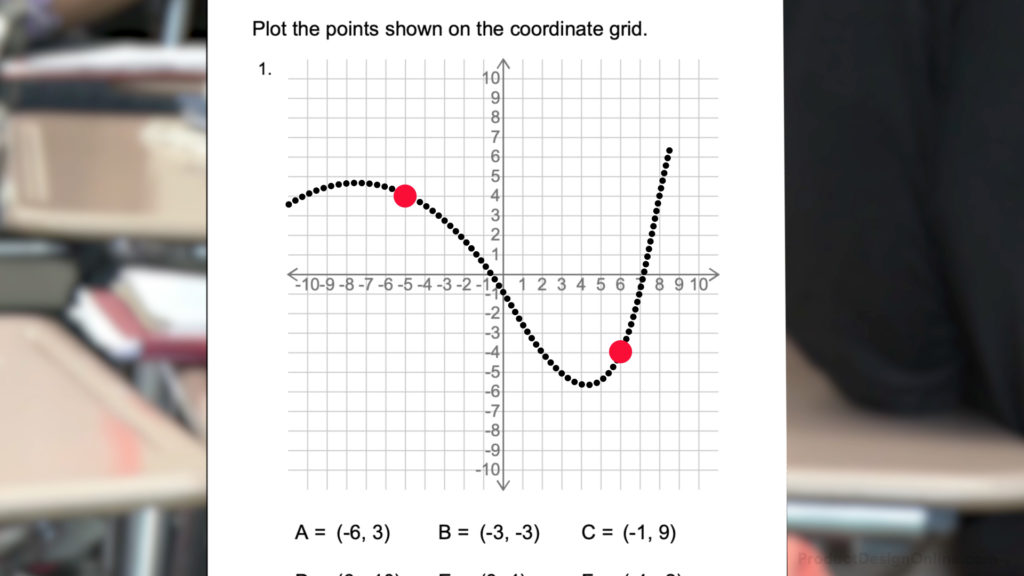

The instructions (G-code) tell the Extruder (or where the plastic comes out) to move to a new location on the X and Y-axis. This process takes place for every single layer. The movements work similarly to 5th-grade math students who are plotting points who plot points on a coordinate plane. Each X or Y coordinate point exists in the instructions in a strategic order. Most often by the most efficient order (i.e. shortest printing time). Just like you may put frosting on a cake, the 3D printer Extruder will continue to move to every sequential point as the material comes out of the nozzle.

The Extruder moves point-to-point, laying down material until the shape of the individual layer is complete. All FFF 3D Printers include a small fan that helps cool the filament after it comes out of the Extruder. The fan helps the plastic solidify into the desired shape while adhering to the previous layer.

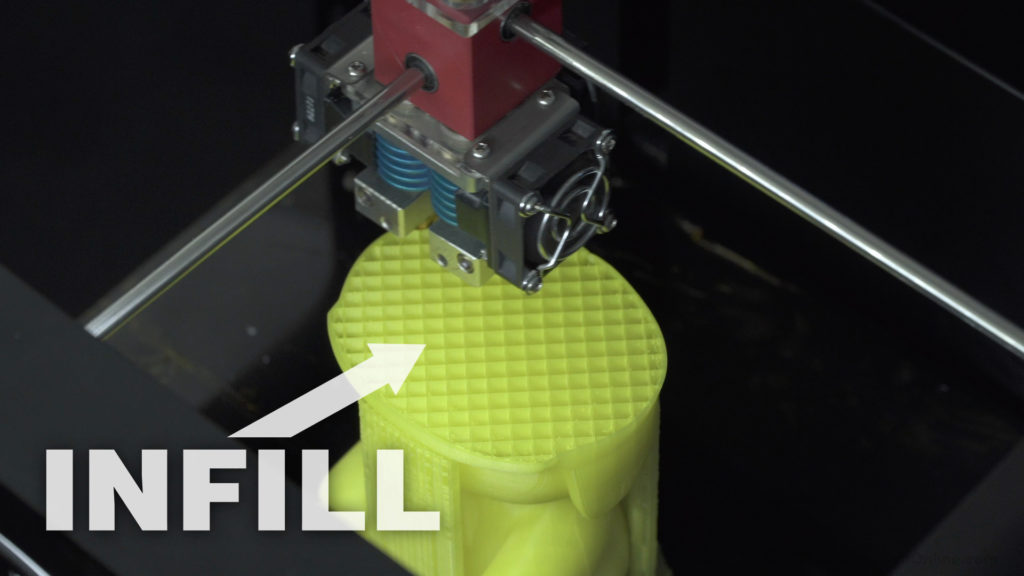

Through the infill process, the 3D printer will fill in the inside of the outline. The infill will range from 5-100% to provide the final object with the necessary structure. Infill is mainly used as a method to reduce material usage and printing timer, instead of having the model printed 100% solid.

The Extruder moves upward in the third dimension or the Z-axis once a 3D print layer is complete. This movement is very subtle and matches your layer height, as set in the “Slicing” software (commonly 0.1 or 0.2mm thick)

This process repeats for each layer until your desired part is complete.

For complex parts, extra material is printed to temporarily hold or support overhangs and protrusions.

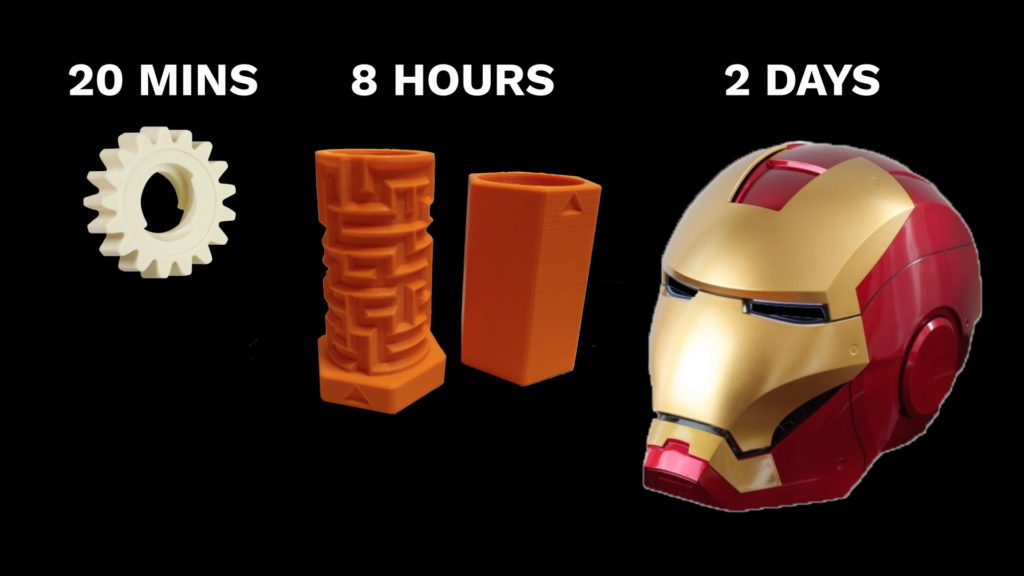

3D prints can take anywhere from twenty minutes to several hours or days to finish. This all depends on the size and complexity of your design. Your chosen material, model of 3D printer, and settings defined in the slicing software will all play a critical role in determining the time.

Design of a 3D Printer Machine

There are countless 3D printer machines with different designs, but all FDM (FFF) machines have a few things in common. Each FDM 3D printer has an X, Y, and Z-axis, which allows it to work in 3-dimensions. Compare this to your home office printer, which only moves along the Y-axis, while the paper moves in the X-direction.

All FDM machines have a Hotend or a part that heats room temperature plastic to a hot and consistent temperature. Heating the plastic allows a compact motor to push the plastic through the Extruder Nozzle, turning the selected material into a workable state. In other words, imagine if you strapped a hot glue gun to a robot.

How 3D Printers Create Your Design

You’ve seen the stunning 3D prints and are wondering, “how do 3D printers know how to create your design?”

Like most computer-controlled machines, you will have to provide it with a set of instructions. Fortunately, this is much easier than you might think.

Your design can start with two main workflows.

First, you can design your 3D model from scratch, using 3D modeling software such as Fusion 360, Shapr3D, TinkerCAD, Blender (and more).

The second route is to download 3D models from several community-based websites. Websites like Thangs, Thingiverse, and Cults3D offer free and paid 3D models, many of which are ready to 3D print. These sites offer both practical 3D Prints in addition to decorative and fun objects (e.g. Minifigures, puzzles, etc.).

Cost of Consumer (Hobbyist) 3D Printers

The cost of consumer-level 3D printers has gone down tremendously in the last decade. In 2022, entry-level 3D printers are under $500, with reliable starter printers as low as $100 to $250 (US Dollars).

Choosing a 3D printer can be tricky, as there are many variables to consider, and it ultimately depends on your needs. We encourage you to learn more in our post about recommended 3D printers for Hobbyists.

For your convenience, we’ve also listed some of the most popular 3D printers that we recommend.

Recommend 3D Printers

- Beginner [sub $200] ➞ https://geni.us/kingroon3d

- Beginner [sub $300] ➞ https://geni.us/Ender3proV2

- Beginner [sub $400] ➞ https://geni.us/magicianx

- Intermediate [sub $800] ➞ http://bit.ly/prusa3dp

- Prosumer [Kevin’s 3D Printer] ➞ https://bit.ly/kevins-printer

3D Printer Filament (1.75mm)

- PLA ➞ https://geni.us/InlandPLA

- ABS ➞ https://geni.us/InlandABS

- PETG ➞ https://geni.us/InlandPETG

3D Printer Filament (2.85 or 3mm)

- ABS ➞ https://geni.us/InlandABS3mm

- PLA ➞ https://geni.us/Inland3mm

- PETG ➞ https://geni.us/InlandPETG3mm

Drawbacks of Consumer 3D Printers

Despite their low cost and growing adoption, you’ll find there are still many drawbacks of consumer-level 3D printing. Both FDM (FFF) and SLA have their drawbacks. We’ll focus on the downside of FDM 3D printers.

First, not everything can be 3D printed. There are limitations to material strength, orientation, obtaining 3D models, and more.

One of the biggest drawbacks to home 3D printing is the “layer lines”. Both FDM and SLA will produce results that include small layer lines, depending on how the model was sliced-up. At a minimum, this is is an aesthetic issue, as the surface is never smooth. Layer lines are also a concern for structural reasons and make 3D prints less food safe or not food safe at all (despite what many are misled to believe).

Lastly, time is another drawback that is often not considered. 3D printers are machines, and just like cars, they require regular maintenance. If you’re not one to enjoy tweaking or DIYing things, then a consumer-level 3D printer may not be for you.

Summary of How 3D Printers Work

To summarize, start by creating your design or downloading a 3D model from the internet. Load that into your free Slicing software and generate the G-code that your 3D printer can read as the instructions.

Your 3D printer will then interpret the instructions, layer by layer, as it lays down plastic or other composite materials. The plastic will continuously push through the Extruder as the Extruder moves from point to point. This process will repeat for every sequential layer until your desired part is complete, taking anywhere from a few minutes to a few days.

-

Autodesk rebrands Autodesk Fusion 360 and Changes Prices (Jan 2024)

In January of 2024, Autodesk, Inc. quietly started rebranding their Autodesk Fusion 360 CAD/CAM product as ‘Autodesk Fusion,’ officially dropping the ‘360’ from the name. This rebranding coincides with a new pricing and packaging structure (announced in November 2023) that affects all Autodesk Fusion Commercial license holders.

Leave a Reply