STL files are common when dealing with CAD and 3D printer “slicer” software. STL files are easy to save(keyboard shortcut CMD/CTRL+S) Saves the file that is currently open. More and don’t take up much memory. However, they can not be edited directly and are prone to errors or flaws in the model’s geometry.

A different file type exists to alleviate some of these problems while still being quick, easy, and memory efficient. It’s called 3MF.

What are .3mf files?

Most importantly, you can edit many parts of the metadata, eliminating the need to repeatedly save new files. This saves time when editing and troubleshooting when compared to creating a new STL each time.

3D Manufacturing Format (.3mf) was created as an open-source projectProjects the body silhouette, edges, work geometries and sketch curves into the active sketch plane. Use the selection filter to project a specific type of geometry or the body silhouette. More to create files specific to additive manufacturing. Similar to .zip extensions, a .3mf file can hold multiple models together, slicer settings, manually created supports, units and measurements, and even colors to be used for multi-colored 3D prints.

Who designed .3mf files?

The 3MF Consortium created and continues to lead the development of the .3mf file. The Consortium was founded by Microsoft but now includes many other well-known companies in the 3D printing and modeling industry. This includes Autodesk, Ultimaker, 3D Systems, Prusa, and more. Despite designing this highly specialized file type, 3MF will always be free to use. The Consortium is a non-profit highly interested in optimizing files to be 3D printed.

Advantages over .stl files

Storage – Despite saving a lot more details and information, using a .3mf can save memory when compared to the basic .stl file. One example of how using .3mf manages this is when creating copies of a model. When a model is duplicated in a .stl file the number of saved triangles is also multiplied. However, a .3mf file is more efficient, simply noting that there is another instance of the file and where that instance is located. Long term, it is also more efficient by simply editing existing files rather than constantly creating new STL files.

Editability – an STL file can no longer be edited once saved. In Fusion 360, if a simple cube is exported as an .stl and then immediately reimported it becomes far harder to work with, as Fusion 360 (and other parametric programs) force the user to edit the triangles that make up the form. On the other hand, a .3mf file allows the user to edit any of its characteristics individually.

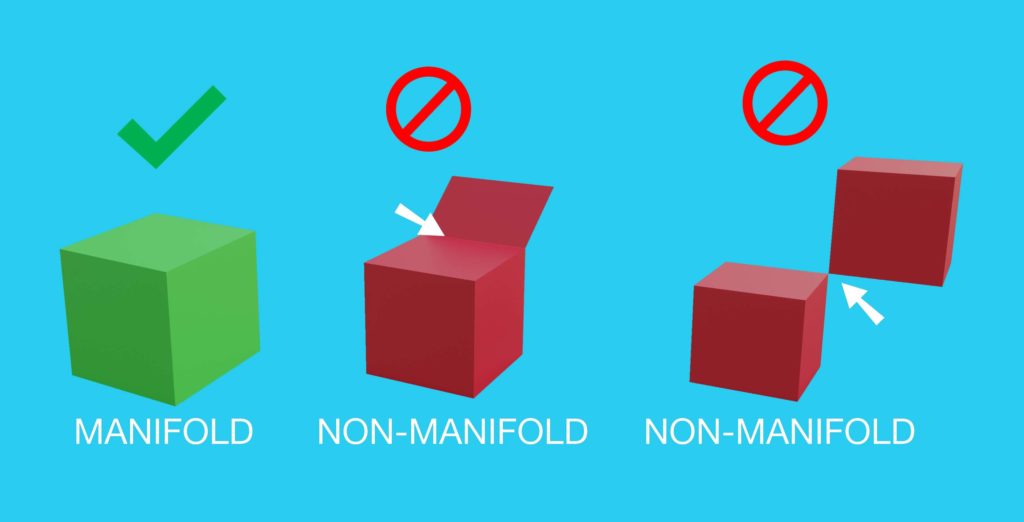

Defined edges – STL files merely contain the model-based as a large number of triangles creating the 3-dimensional mesh of the body. Most of the time this works out, however, it leaves the possibility of non-manifold edges or holes appearing in the model. Non-manifold edges consist of geometry that cannot physically exist, including single unconnected planes, intersecting planes, and edges connected to more than two planes at once. None of these can physically exist, making them difficult to deal with when creating 3D printed copies. 3MF files are always completely defined.

XML-Based – 3MF Files allow for both public and private extensions. This allows 3mf files to be used for a wide variety of software and purposes. Currently, the main drawback of 3mf is the lack of widely adopted support. 3mf will likely replace STL files as more software packages and companies adapt this file type.

Leave a Reply